The method of running barges under pushing was originated in large rivers in U.S.A. and, nowadays, this method is widely employed in many large rivers in the world. But, the history of its use as a means of open-sea transport is not so long and goes back about 30 years only and, even now, pushed barges are considered means of transport in shorter routes and not trans-ocean transport, mainly because the speed of a pusher-barge combination is unexceptionally lower than that of ordinary cargo ships and tankers of same loading and same engine power.

But, in shorter routes in which the speed and fuel cost have a comparatively lower importance, the pusher-barge combinations with lower personnel expenses exhibit their excellent advantages over conventional cargo ships.

When, for example, several barges are operated in a short route of service, such as lighterage service, the conventional rope-towing has so far been used as a common practice in most cases. But, in such a service, introduction of the pushing system, particularly mechanically connected one, can improve the operational efficiency remarkably through raising the running speed and saving the time needed for berthing, unberthing and exchanging barges, and, at the same time, the safety of operation is likewise improved. The advantage of pushing over towing can be easily understood from the comparison below.

| Pushing versus Towing |

| (a) |

The pusher-barge combination is much shorter in length than the tug-barge train towing by a rope. This shortness means a higher safety. |

| (b) |

The pusher-barge combination can stop itself by its own power, while the towed barge has no power to stop itself. |

| (c) |

The pusher-barge combination can choose its running course by its own power, while the towed barge cannot do it. The combination of (b) and (c) assures a much higher safety and a much better manoeuvrability of the pusher-barge combination. |

| (d) |

As a result of (b) and (c) above, the pusher-barge combination can berth and unberth itself by its own power in a short time. As is well known, berthing and unberthing of a towed barge require much longer time and troublesome works. |

| (e) |

The speed of a pusher-barge combination is unexceptionally higher than that of a towed barge when the deadweight and engine power are same. |

| (f) |

The pusher-barge combination has a better course-keeping quality than the towed barge which often swings to the left and right when being towed. This is because the pusher hull connected at the stern of the barge functions as an enormous skeg for keeping straight course of the barge. |

| (g) |

When several barges must be operated alternately in a short route, the time needed for exchanging barges is very important. Exchange of towed barges will need 20 - 30 minutes and, in addition, at least one crew member must go over to the barge for handling the tow-rope, while a pusher having mechanical coupler needs 30 - 40 seconds only for disconnection and connection respectively and the exchange of barges can be finished in several minutes, and, further, no crew member need to go to the barge. This difference has a considerable influence on the available number of services per day. |

| (h) |

Small towed barges often have rudders and, accordingly, need helmsmen on board. Most bigger barges have no rudder and, accordingly, are very difficult in manoeuvring. On the contrary, the manoeuvrability of a pusher-barge combination is same as that of a conventional self-propelled ship. |

There are two types of connection in pusher-barge combinations --- rope-connection and mechanical connection. The merits of the latter over the former are easily understood from the comparison stated below.

| Mechanical Connection versus Rope-Connection |

| (a) |

The seaworthiness in wavy sea of the rope-connected pusher-barge combination with the most advanced method of connection has a certain absolute limit at a fairly low level, while the mechanically connected pusher-barge combination can be designed and constructed for unrestricted service if so desired. In sheltered waters, a fairly simple method of mechanical connection can be applied to assure a satisfactory performance. |

| (b) |

The rope-connected pusher-barge combination requires 5 - 8 crew members and 10 - 20 minutes of long time for connection, and even the disconnection requires similar number of crew and 5 - 15 minutes of time. The work of connection and disconnection is muscle work to be carried out even in rainstorm on the slippery wet deck. Particularly when a pusher is required to operate several barges alternately in a short route, the long time needed for connection and disconnection for repeated exchange of barges is a big problem affecting the available number of services per day and, in addition, an increased number of crew members may be required for efficient exchange of barges. In mechanically connected pusher-barge combination, connection and disconnection are effected in 30 - 40 seconds only by the captain's remote-control from the bridge. |

| (c) |

In the rope-connected pusher-barge combination, crew members must go to the barge for handling ropes before connection and return from the barge after disconnection even when the pusher is oscillating due to waves.

In the mechanical combination, connection and disconnection are effected one-sidedly from the pusher and crew members have no need of going to the barge. |

| (d) |

The inevitable looseness in connection of the rope-connected pusher-barge combination permits angular deviation (loss of coincidence of centerlines) of the pusher and barge, and this phenomenon occurring at the first stage of steering will cause delay of response of the barge to steering of the pusher. In other words, the pusher deviates first relative to the barge and, thereafter, turning of the barge begins.

In mechanically connected pusher-barge combination, such a delay of response does not occur and the motion of the combination is same as that of a self-propelled ship. |

| (e) |

In rope-connected combination with inserted rubber fenders between the pusher and the barge, shocks, vibrations and noises uncomfortable to the crew are inevitable.

In mechanically connected combinations, such uncomfortable phenomena are not present. |

As may be easily understood from the above statements, the operational efficiency of pusher-barge combination, particularly mechanically connected one, is so higher than that of towing that the additional cost for introduction of pushing system can be recovered in a short time.

The 2-pin supporting articulate couplers ARTICOUPLE have been proven in their practical use to realize all the merits enumerated above.

In spite of the above-explained rationality and high efficiency, and, in addition, the good sea-worthiness realized by introduction of mechanical connection system, however, pusher-barges could not compete economically with conventional cargo ships in longer routes. The reason is the lower speed of the barge train and, if a comparative speed is desired, big fuel consumption due to enormous power requirement deteriorates the profitability remarkably.

The cause of the low speed is the large resistance due to eddies occurring in the wide clearance between two hulls which cannot be dispensed with to permit freedom of relative pitching of the articulately connected train.

The 3-pin supported rigid connection system, TRIOFIX, was introduced to give a solution to this problem. This new method of connection involves a possibility to design favourable hull forms relationship with least generation of eddies and, at the same time, to afford comfortable- ness to the crew through eliminating the heavy pitching of the pusher in waves.

Even TRIOFIX-connection cannot realize a perfect eddiless combination, but it can limit eddies so well that the speed difference may be in the order of 0.1 - 0.3 knot when the hull forms are well designed, and its introduction will open up a possibility that the routes where pusher-barge combinations are economically operable will be much elongated.

The above explanations exhibit the advantages of pusher-barge systems as means of simple cargo transport. These advantages are still partial, and there are other important advantages --- manoeuvrability and quickness in motion --- which can be exhibited at harbour works and in harbour/marine construction sites, together with time- and manpower-saving, higher safety for crew, etc.

|

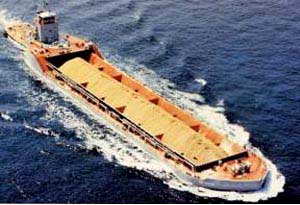

| Akashi-maru & dump-barge |

| |

|

| Mini-pusher running floating crane |

At the sites of harbour/marine construction, various kinds of large workvessels are operated --- floating cranes, pile drivers, dredgers, dump-barges, various barges for transport of materials, etc. These large workvessels, if built as non-selfpropelled vessels, have so far been moved by rope-towing. The preparation for towing needs a long time and much muscle works and, after towing, stopping of towed large vessels at a pre-determined position is not easy. For example, the long time needed for pre-positioning of floating crane sacrifices the time of the main crane work. Large floating cranes are often built as self-propelled ships to realize easier pre-position-Ing and, in spite of few chances of long navigation, has many highly qualified officers corresponding to the big hull which must correspond to the crane capacity. There are similar cases in regard to other kinds of vessels.

Introduction of pusher system will bring about a remarkable improvement of efficiency through high degree of time- and manpower-saving. If a pusher is introduced into the marine construction side, other workvessels, such as floating cranes, etc., can be non-powered vessels needing no high class officers, and the time needed for preparation before their main works can be remarkably saved. In such a case, it is indispensable to standardize the coupler and the arrangement of connecting parts of all the related vessels so that a complete swappability may be maintained. It is further recommended that the pusher(s) will be arranged for conventional towing, as "pusher-tug", and, in some cases, also for pushing under rope-connection. It may even be possible to utilize the pusher as a multi-purpose service boat having other functions, such as anchor tender service, hydrographic survey, diver boat service, etc.

The couplers with friction components can adapt themselves, under control, to the change of draught of barge due to loading and unloading. This character has widely been utilized on a number of dredging barges taking sand by suction from sea bottom in 3 - 4 metres high waves.

Different from those of pure multi-step tooth-engagement principle, couplers with friction components can connect even when the pusherboat is more or less oscillating due to waves. This character may be useful in some cases in the field of offshore activities.

In the past 30 years, several types of couplers have been developed to meet multifarious types of demands from the clients. Nowadays, ARTICOUPLE and TRIOFIX can cover all probable types of needs for pusher-barge systems.

|